Chardon Engineering was a founding partner of CEVAP Technology (stealth mode 2015-2016, founded 2016, exited 2018). CEVAP has developed a novel technology for water purification using residual heat/heat pumps and is still active -and growing-.

Following the endeavours of CEVAP Technology, Chardon Engineering proceeded in the field of harnessing residual heat for environmental challenges, by developing the Condensing Dryers. Designed to remove the high energy costs of drying for many biobased and circular resources, the development culminated in the founding of Multiphase Dryers BV in 2022. Having transferred all relevant IP and assets into Multiphase Dryers, Chardon Engineering is currently mainly a private holding of founder Merlijn Chardon.

Chardon Engineering is specialized in technology development and product development, mainly in the areas of harnessing residual energy and heat and flow phenomena. We do so with a hands on approach, using purpose built test set-ups and prototypes, to demonstrate feasibility and iterate quickly towards products that are both technically, sustainably ánd economically feasible.

We are driven by the urge to make a difference, saving energy, converting waste streams into new resources and relieving end-users from high energy bills and waste removal costs.

Engineering philosophy

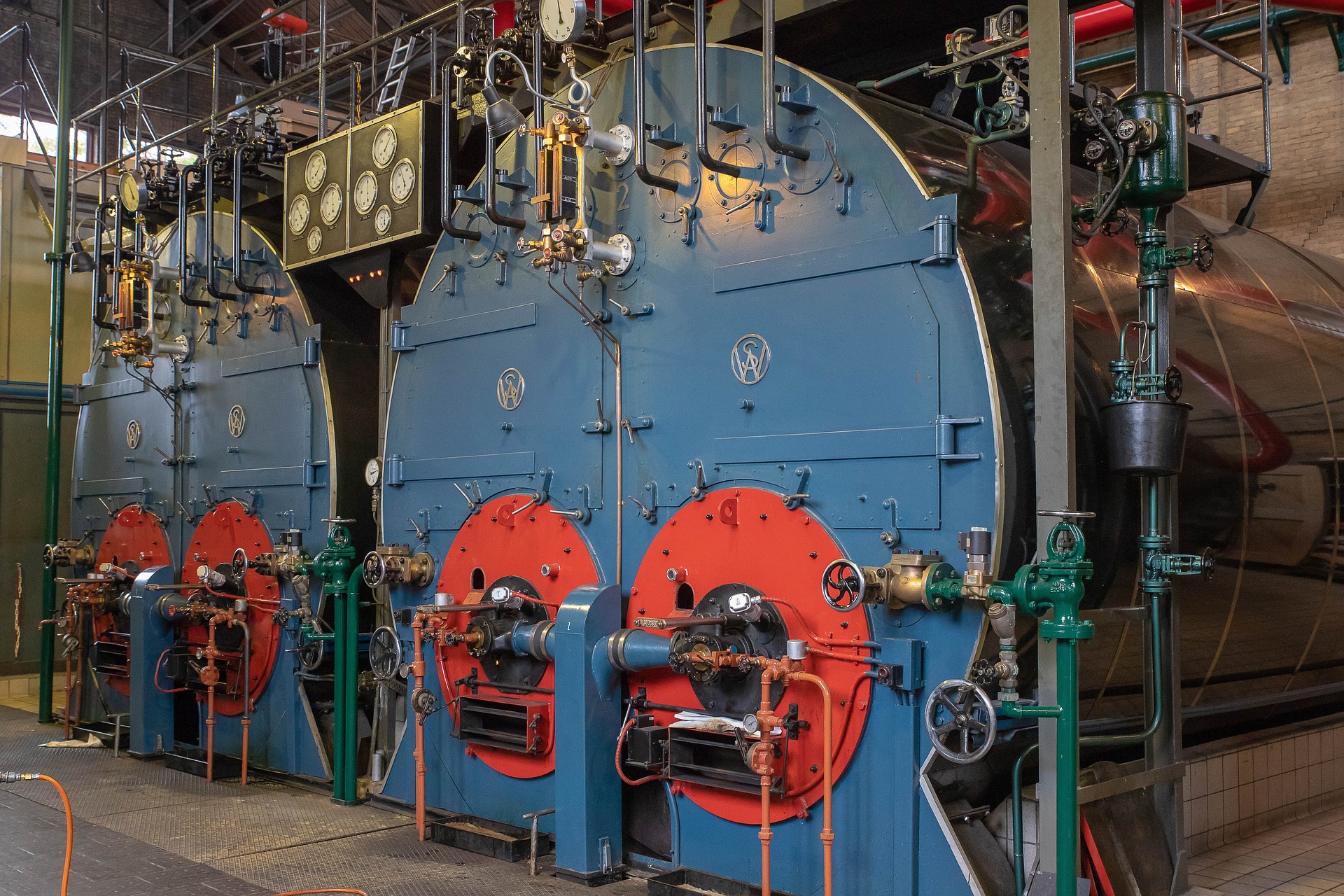

During the days of affordable and abundant fossil fuels, industrial thermal equipment was engineered to operate using high temperatures. These high temperatures allowed engineers to limit the size of expensive metal heat exchangers, hence the capital costs of their devices.

But due to the transition from a fossil fuel powered economy towards a society that is increasingly powered by renewable energy sources and recovered waste heat, the available temperatures to drive equipment lower significantly.

This implies that the current design methods are no longer economically viable, especially for low margin bulk products.

Over the years, Chardon Engineering has developed a set of techniques to economically harness low temperatures, combining knowledge from the world of physics, with modern materials and production technologies, such as 3D printing.